|

I don't own a dust collection system and my work table is indoors, not in a garage. Out of consideration for my lungs and distaste for housekeeping I needed a convenient way to collect the dust.

What I had to work with is a small shop vacuum purchased at a home improvement store.

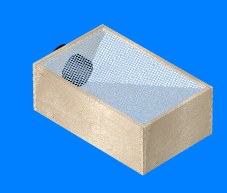

A few years ago Masterpiece Models (I lust for their Time Machine kit) sold a very nice modeler's sanding box made of ABS plastic, but this item is no longer available. I decided to try to design and construct a substitute.

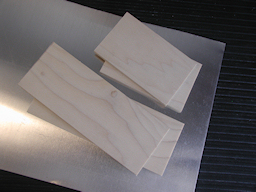

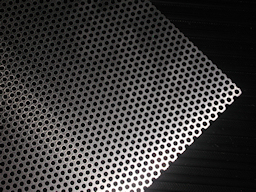

The most obvious factor in the design was that the box be large enough to provide a comfortable work surface but preserve sufficient suction that the dust is effectively removed. John Geigle of Masterpiece Models responded to my inquiry and provided the dimensions of his unit (roughly 10 x 5 inches), which he said was small enough for most vacuums to handle.

NEXT PAGE

NEXT PAGE